Highlights

Analyze the unique thermal behavior of materials and their components

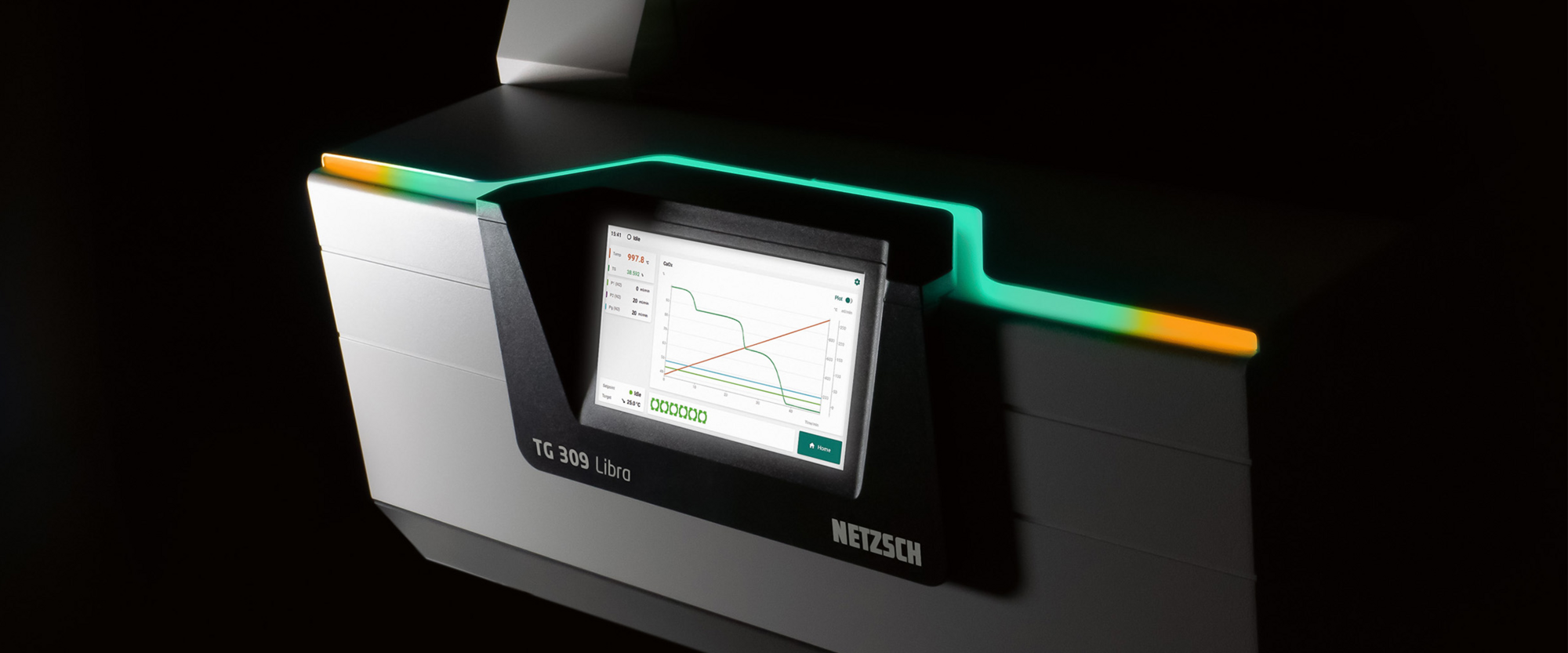

The TG 309 Libra Select is the instrument which offers the greatest variety in the Libra series. Temperature ranges from 10°C to 1025°C or up to 1100°C can be selected. It offers outstanding balance resolution for detecting even the smallest of changes in a material's mass. In addition, it offers the ability to couple to to gas analysis and the possibility of being equipped with a large, 204-position ASC (Automatic Sample Changer).

Get Results Faster Without a Baseline Run

To ensure accurate mass change values, a baseline run is typically conducted under test conditions that are identical in terms of heating rate, gas type, and gas flow.

The baseline takes factors such as heating rate, crucible type and geometry into account while also accounting for instrument and buoyancy effects, thus allowing these to be subtracted from the sample measurement.

The TG 309 Libra typically eliminates the need for a separate baseline run when using the integrated BeFlat baseline run for typical temperature measurements. This significantly speeds up tests.

20 Times Faster Thanks to High Heating Rates

The TG 309 Libra has a low-volume furnace. It supports rapid heating rates of up to 200K/min over the entire temperature range and fast ballistic cooling from 1100°C down to room temperature. This allows for faster analysis results, even at high temperatures, with a turnaround time of just a few minutes.

More Comprehensive and Faster Characterization by Patented c-DTA

In direct contact with the sample crucible, the sample thermocouple measures temperature variations in the material. This enables more thorough characterization of sample properties and determination of endothermic (e.g., melting) and exothermic (e.g., oxidation) effects during thermogravimetric investigations. In addition, c-DTA allows for temperature calibration using DSC reference materials.

Method

Thermogravimetric Analysis / Thermogravimetry

What is Thermogravimetry?

Thermogravimetry has the ability for differentiation between individual components based on their distinct thermal behavior. By analyzing weight-loss profiles, users can deduce the composition of complex samples, enabling deeper understanding of their structure and properties.

Revealing the Mysteries of Complex Mixtures and Material Transformations

Thermogravimetry (TG) is renowned for its precision and sensitivity. By subjecting a sample to controlled temperature increments while continuously measuring its weight change, TGA can detect even the slightest alterations in a material‘s mass. This level of sensitivity allows for pinpointing the exact temperatures at which various transformations occur, such as decomposition, volatilization, or oxidation. As a result, TGA provides valuable insights into a material‘s composition, providing such information as stability and degradation data for polymers along with data for material characterization and formulation.

Ensuring Product Quality and Safety

For industries like pharmaceuticals, chemicals, and food, ensuring product stability is very important. Thermogravimetry plays a vital role in evaluating the thermal stability of materials over time. By subjecting samples to extended thermal cycling, researchers can assess their long-term stability, obtain initial information about shelf-life, and identify potential degradation pathways. This information is critical for quality control and regulatory compliance.

Unlimited Versatility: Tailored for Diverse Applications

One of the remarkable qualities of thermogravimetry is that it can be adapted to a wide range of applications. From the polymer industry to materials engineering, and from pharmaceutical research to environmental science, TGA is a versatile technique that transcends disciplinary boundaries. Its capability of providing fundamental insights into materials makes it indispensable for materials characterization, from quality control to industrial research and academic applications.

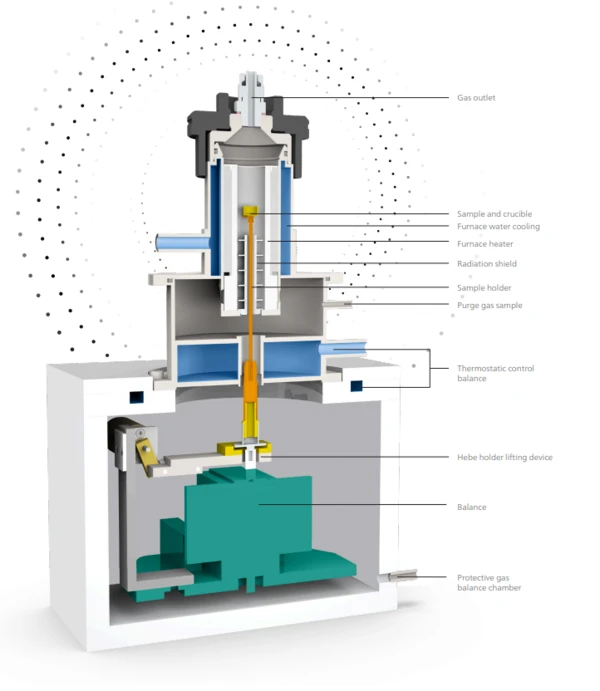

Measuring Principle

Thermogravimetric analysis (TGA) is a precise analytical technique used to track changes in the mass of a sample over time and/or temperature under a defined and controlled environment with respect to heating rate, gas atmosphere, flow rate, crucible type, etc. It can accurately detect weight changes down to fractions of a microgram. This high sensitivity allows for the determination of even the smallest changes in the physical and chemical properties of a material.

Specifications

Technical Data

Temperature range

Balance resolution

Heating and cooling rates

Cooling time:

12 min (1100°C to 100°C)

Wide measuring range:

2000 mg

Vacuum-tightness:

<< 10-1 mbar

Sample crucible volume:

up to 350 µl

Atmospheres:

inert, oxidizing, reducing, static, dynamic

Automatic sample changer:

ASC with 204 positions optionally available

High-End 204-Sample ASC and Removable Sample Trays

The TG 309 Libra® Select and Supreme ASC is designed to hold two interchangeable sample trays in microplate format, each holding 96 samples. This allows for clear assignment of the samples when they are prepared away from the instrument. An additional fixed strip is reserved for up to 12 calibration materials or empty crucibles of different dimensions and materials for calibration and correction purposes. Of course, correction measurements with empty crucibles can also be defined on the trays.

Software

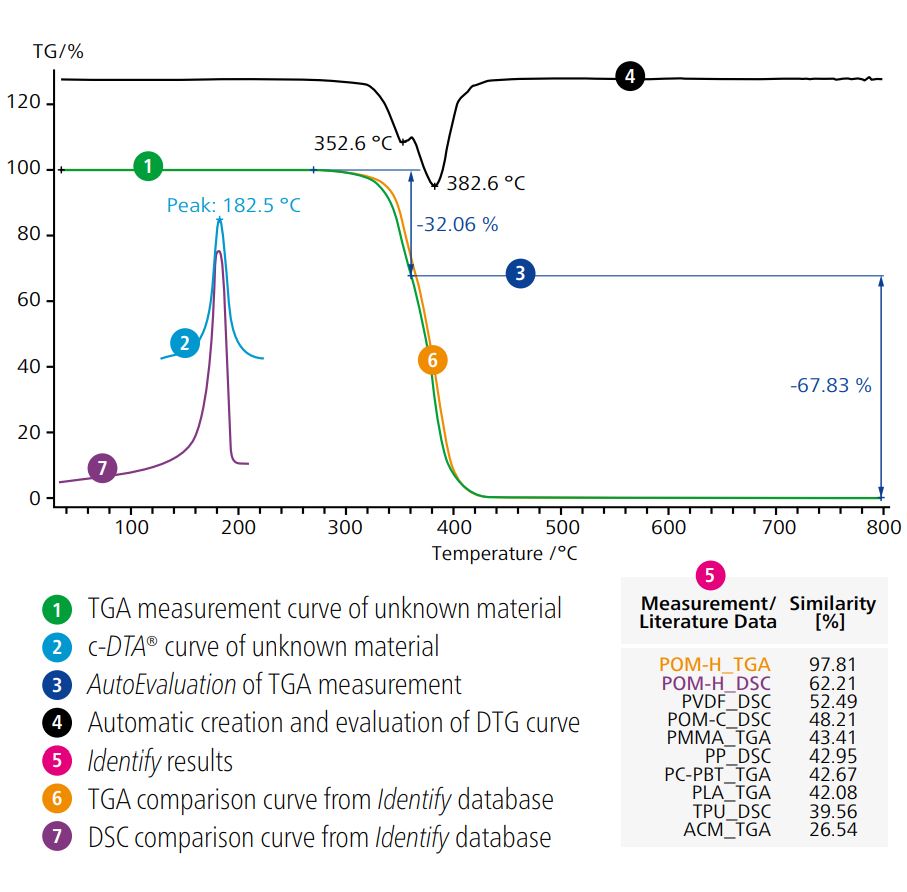

AutoEvaluation

Objective Results Right After a Measurement

AutoEvaluation is a self-acting evaluation routine for thermogravimetric (TGA) measurements. It autonomously evaluates all significant mass changes, including mass loss and mass gain, instantly; generates the DTG derivative curve; and automatically evaluates the corresponding peak temperatures. When incorporated into a measurement method, evaluated TGA and DTG curves appear immediately after the measurement is completed. Moreover, users can customize the size of mass changes to be detected and the selection of evaluation results to be displayed.

Identify

The Database for Material Identification and Quality Control

Identify is a unique software tool in the field of thermal analysis for the identification and classification of materials. Besides 1:1 comparisons with individual database measurements or literature data, it is also possible to compare a measurement with classes (groups of measurements or literature data). Such classes can consist of data of the same material type, allowing for material identification. A class can also contain reference curves for pass/fail testing in quality control. The included NETZSCH libraries contain more than 1300 entries from the application areas of polymers, organics, pharmaceuticals, food, cosmetics, inorganics, ceramics, metals and alloys. Signal types currently supported include DSC, DSC cp, TGA, STA, DIL/TMA and DMA. Users can expand the database with libraries containing an unlimited amount of their own data. Ultimately, this growing collection of database entries and measurement conditions can also be extremely useful in preparing future experiments.

It is particularly advantageous that Identify can even simultaneously incorporate two types of measurements, such as TGA and DSC or c-DTA®, during identification, this can significantly reduce multiple interpretations, and thus increase the chances of correct material identification. As shown in the example, the evaluated TGA and c-DTA® curves can be used together by Identify: Analysis reveals that the TGA decomposition result is very similar to that of the POM-H polymer found in the database; also, there is a DSC curve for POM-H that agrees well with the melting effect at a peak temperature of 183°C, which is also reflected in the c-DTA® curve of the input measurement. The material is thus identified as POM-H material with high confidence; all other polymer types present in the database can be ruled out.

Eco Mode – Uses Energy Only when Needed

FOCUS ON EFFICENCY AND A MORE SUSTAINABLE LABORATORY

To obtain accurate thermogravimetric results with low drift, a thermostat is used to condition the instrument. A constantly running thermostat not only consumes energy, but also produces waste heat that must be controlled by air conditioning systems.

On a busy day in the laboratory, the TGA instrument will be in use for around 10 to 12 hours. If no measurements are scheduled overnight or over the weekend, the instrument will either have to be shut down, resulting in a stabilization time before it can be used again, or it will remain on, consuming energy that is not technically required. Sustainability in the laboratory environment is becoming increasingly important.

The TG 309 Libra® offers an energy-saving Eco Mode, which allows the chiller to be switched off automatically via software, making it much more economical to run. The software provides a user-defined schedule to activate either Idle or Eco Mode. This eliminates the waiting time that would occur if the instrument was completely shut down, by reactivating the gas flow and thermostat as required, so that the instrument is ready for the first measurement on schedule. Switching the unit to Eco Mode will save 1 kW of electricity, which can sum up to over 6000 kWh per year. This makes the instrument cheaper to run and effortlessly reduces your carbon footprint

GET IN CONTACT

Scan the QR-Code with your smartphone

You still have questions and would like to be contacted by our sales department? Would you like to receive a quote for the product? Do you need a poster or brochure for one of our products? Just Scan the QR-Code!